PanPHE gasketed plate heat exchangers are designed with easy access for regular servicing and for a long, low-maintenance lifetime with low life-cycle costs.

It consists of a plate pack of a calculated number of corrugated plates with perimeter gaskets clamped securely with tie rods between two thick carbon steel plates. The plates have openings at the corners to direct process and service fluid flows through the interplate passageways. Fluids flow alternately between plates in order to achieve high-efficiency heat transfer. The thin fluid flow and the high turbulence produce low pressure drops and extremely high heat transfer coefficients.

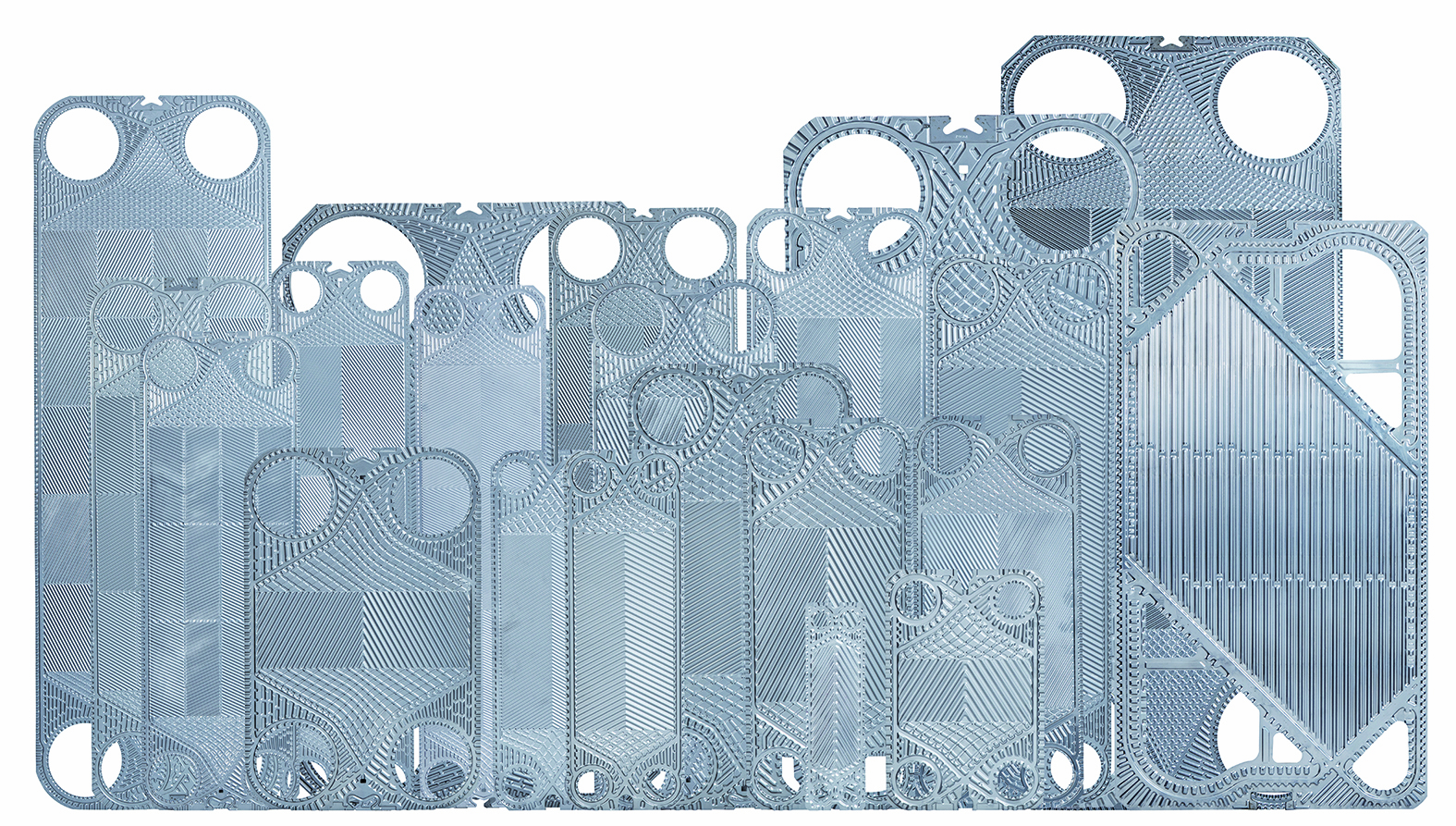

PanPHE plates are pressed in a single stroke by large tonnage hydraulic presses. This enables compliance to extremely tight tolerances, allowing large plate packs to be perfectly aligned in an assembled plate heat exchanger. We use plate material of the highest quality and optimum thickness making our plates more reliable and longer-lasting.

Russian

Russian