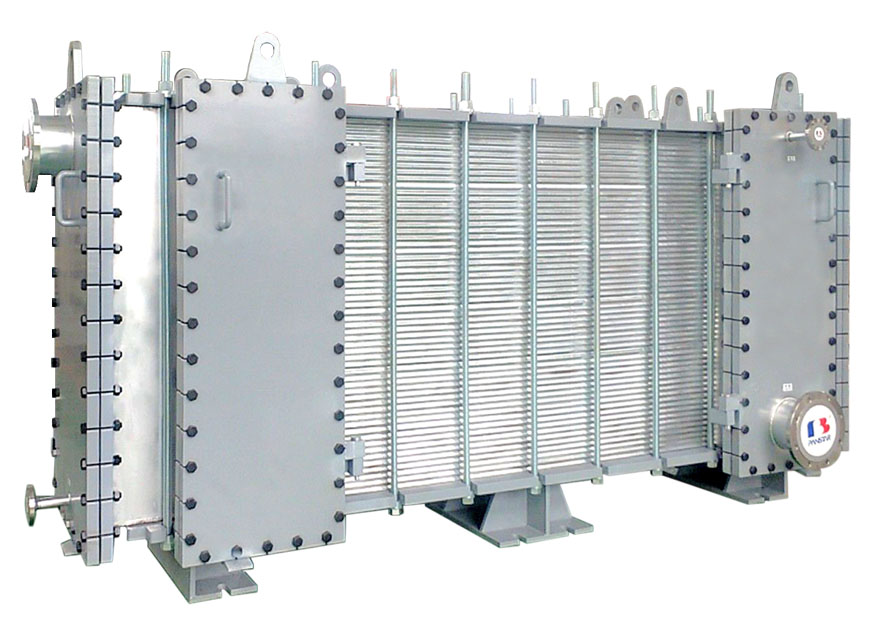

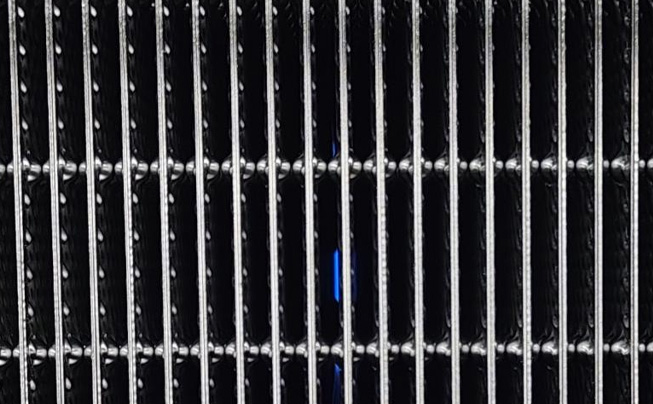

• Wide Gap channel with no interplate gasket

• Accessible on both sides

• Small foot print and compact

• Versatile configuration and geometries

• Proven installations

• ASME U Stamp

• CE Directive 2006/42/EC

• ISO9001

• ISO14001

• ISO45001

• CCS

Whether your application is an lean/rich amine, a slurry cooler or an overhead condenser, there is always a type of plate suitable for your process. From waste water containing fiber in textile industry to sugar and bioethanol production, PanGAP wide gap welded plate heat exchangers help the customers reduce the fouling which leads to longer service intervals and decrease down time. In pulp and paper industry customers benefit from the wide gap channel design to handle pulp fibers without clogging,ensuring continuous operation and energy recovery.In energy intensive processes of petrochemical plants, PanGAP are designed as condensers to recovery the energy, reduce emission and cut the cost of operation.

In vegetable oil refinery process, PanGAP is used to handle the product with high viscosity which minimize the fouling and facilities maintenance. For mining and metal process industry, the unique design of plate with wide gap channel helps to reduce the particle buildup and clogging, at the same time designed with easy opening and cleaning service.

• Oil and gas industry

• Refinery application

• Pharmaceutical industry

• Chemical / petrochemical industry

• Sugar Industry

• Pulp and paper industry

• Vegetable oil industry

• Metal processing and mining industry

AISI 304L

AISI 316L

254 SMO

Titanium

Nickel

Hastelloy

Duplex 2205

2000 m2

Vaccum to 30 barg

-30 to 550 degree C