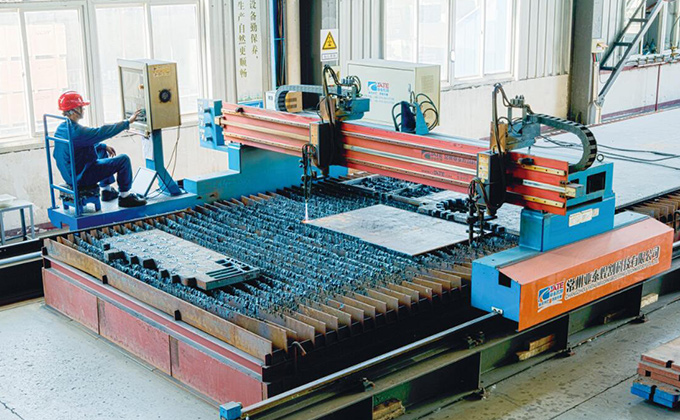

PanStar production factory covers an Area Of 50,000 Square Metres; with workshop area of 17,000 Square Metres

All the plate pressing machines which have the tonage of 3000 Tonnes, 6000 Tonnes, 10000 Tonnes And 20000 Tonnes each are developed and built by PanStar group company. Its in house mould manufacturing center has advanced CNC machine and other equipments which make Panstar has the capability to develop, design and manufacture all different types of plate mould itself, and can customize the design to meet customers' requirements.

Russian

Russian